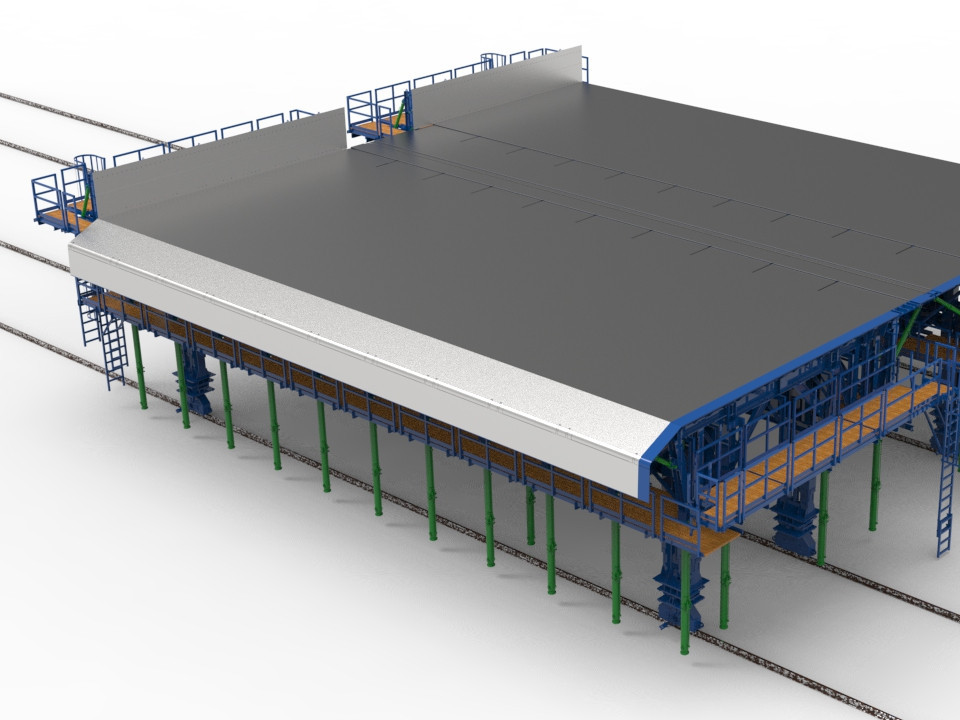

The massive metal structure of the formwork consists of approximately 70,000 components, it is 20 meters wide and 6 meters high. The total weight of the mobile formwork reaches a total of 250 tons.

"We designed the formwork specifically for this type of tunnel with a rectangular structure, which is often used in cities where the space above the tunnel is used for additional road traffic. The structure we developed allows for smooth movement of the formwork as a compact unit. This was a specific requirement for this tunnel because it will be concreted in individual blocks," said CEO Aleš Martínek.

Everything was designed and manufactured to customer specifications in Opava, with an emphasis on rapid movement of the formwork to the next block and efficient positioning in the desired position.

"Compared to conventional methods, the use of mobile formwork is significantly faster and allows for easier assembly on-site. During its development and manufacture, we also had to quickly respond to various changes and requirements that arose from consultations and from the development of the entire challenging project," said Martin Čmiel, Director of the Mining and Industrial Technologies Division.

Before the formwork is handed over to the customer, a trial assembly and verification of all hydraulic functions of the equipment will take place. Customer employees will also be trained on the already assembled equipment before it is put into operation in Norway.

The mobile formwork will be transported from Opava to Norway in a standard way using road transport and a ferry. The breakdown into hundreds of components will allow for rapid assembly on site. We will provide the customer with comprehensive support from assembly to commissioning.

The road tunnel will have a length of 440 m and two tunnel tubes for each direction of traffic after completion. Construction will begin in March 2024 and completion of the first tunnel tube is planned for 12 months. After the necessary technological break, the second tunnel tube will be continued.

"From the perspective of implementation, this is a very complex work in this case. The tunnel is led in an arc and gradually expands. The ceiling of the tunnel will serve as a local road, and therefore some sections have different slopes and others go uphill. That is why we decided to contact the formwork supplier to see if they could provide equipment that would meet the project conditions. OSTROJ was the only company that met our requirements. Skanska SK employees have many years of experience with construction in Scandinavia, and therefore I believe that with the help of such a unique device and mutual cooperation, we can, with high safety standards, build the work on time and to the quality required by the investor," says Juraj Ježek, Regional Manager of Skanska SK.

News

News