Mobile formwork from OSTROJ will be used to concrete the so-called secondary lining of the tunnel, i.e. the outer visible layer that passengers see when passing through the tunnel. "When choosing the supplier of the mobile formwork system, our long-standing tradition of manufacturing machines for underground work, proven quality and flexibility played a key role. We are able to adapt this equipment to the customer's needs throughout the entire development and production cycle," said Aleš Martínek, CEO of OSTROJ.

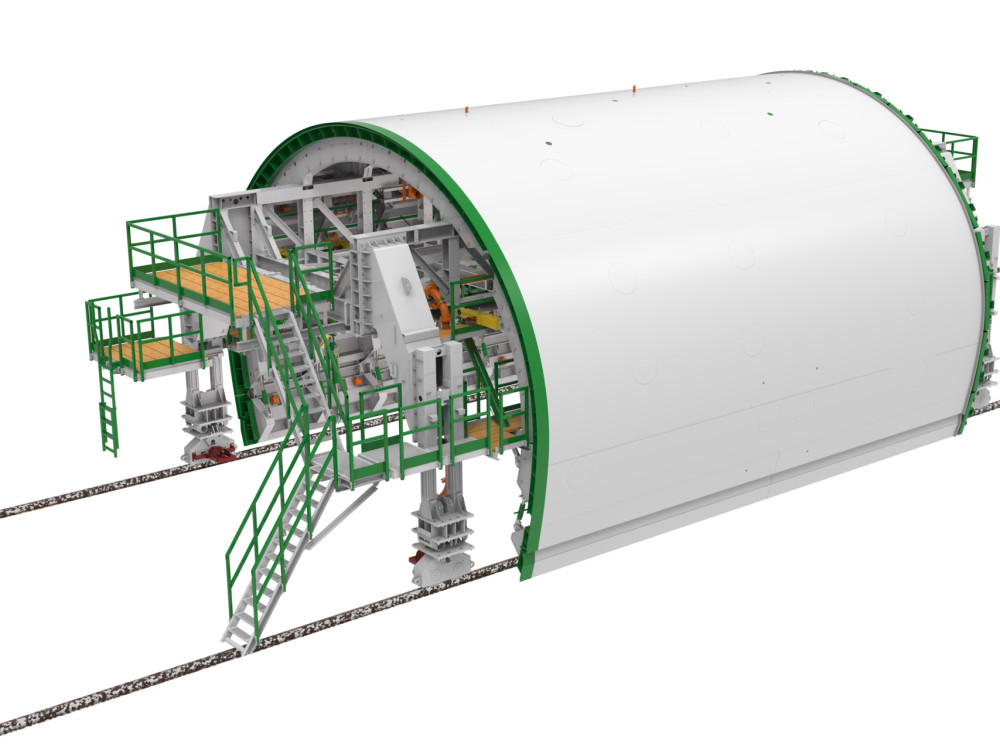

The total delivery includes mobile formwork for double-track tunnels, two small formwork cars for single-track tunnels and a reinforcement carriage, i.e. equipment that will be used for preparatory work before the start of concreting. The larger mobile formwork for the excavation of double-track tunnels will weigh up to 120 tons, be 10 meters long, up to 7.2 meters high and up to 12 meters wide. The equipment for single-track tunnels will be 8 meters long, with a height and width of up to 5.8 meters and a weight of 38 tons.

"The most important phase of development and production is the complete assembly at our plant. This is followed by a comprehensive inspection, which includes verification of all its functions. We test the hydraulic cylinders and the tightness of the hydraulic system separately. This ensures that the final product meets even the most demanding operational requirements," emphasized Martin Čmiel, Director of the Mining and Industrial Technologies Division, OSTROJ.

The parameters of the mobile formwork are carefully adapted to the individual types of tunnels. The equipment is designed to correspond to the requirements for the quantity and speed of concrete pouring. The materials used must correspond to the load of the individual parts of the structure. Simple operation, operating costs and the possibility of easy conversion are also important factors. "We designed the equipment with regard to the variability of tunnel profiles with a view to its easy conversion. This means that the delivery also includes parts intended for the conversion and modification of the mobile formwork for different metro tunnel profiles," added Aleš Martínek.

Depending on the size and type, each formwork will be transported from Opava to Prague by three to eight trucks. The first piece of formwork for a single-track tunnel will be delivered to Prague in June 2024 and will be ready for operation by the end of the month. "At the destination, the equipment will be lowered into the tunnel using a crane and then transported to the final assembly site, which will take 10-18 days depending on the overall size of the mobile formwork used," described Martin Čmiel.

Further deliveries of parts of the mobile formwork will continue during 2025. The Opava company OSTROJ already participated in the development and production of a tunnel boring machine for the construction of the Strahov Tunnel in Prague in the 1980s. Currently, its customers in the field of underground construction include, among others, the company Skanska, for which it is currently manufacturing mobile formwork for concreting road tunnels in Norway.

News

News